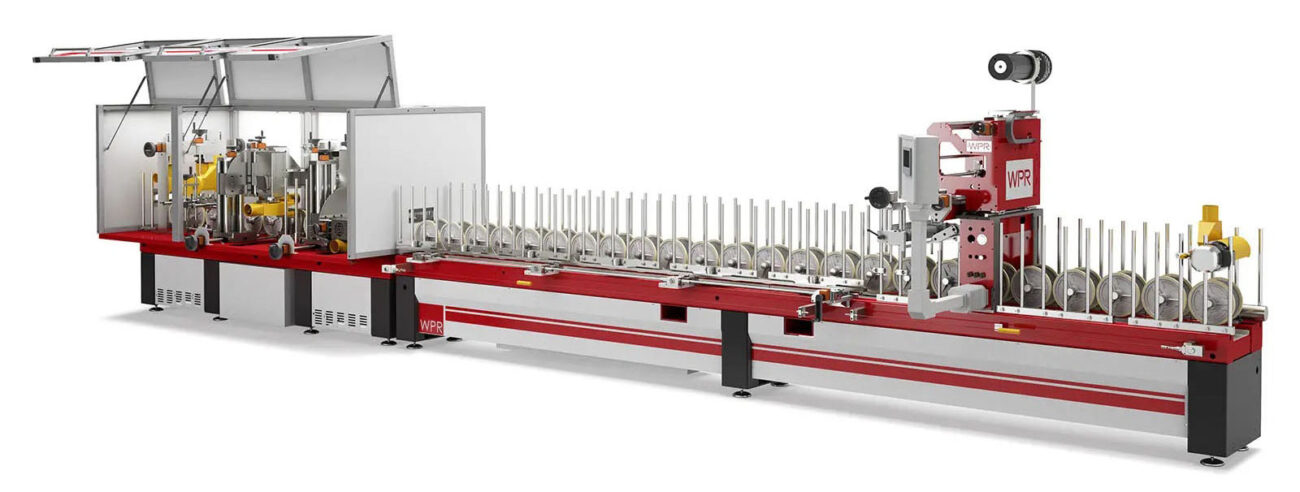

Length of machine

6.000mm - 12.000mm

Maximum foil width

350-1.350mm

The NWA WOOD machine series forms the basis of WPR’s machine range for the wood and furniture industry. Each individual machine is customised to the specific needs of the customer and thus offers the optimum lamination solution in every case.

The right solution for all sizes

Firstly, the wrapping machines in the NWA WOOD series are available in various widths. WPR only uses slot nozzles from their own production, with infinitely adjustable adhesive application widths. This means that different profile sizes and widths can be processed flexibly on the same system.

The possible applications are very diverse: from small wood or MDF profiles for decorative profiles and mouldings, skirting boards or picture frames to door frames, window profiles, drawers, furniture parts and kitchen fronts.

In the largest version, panels for door skins, furniture elements and floor elements can be laminated. The great advantage of applying adhesive by means of a slot nozzle is that profile wrapping, flat lamination and also postforming and wrapping of curved panels are possible on one and the same wrapping machine.

Choosing the right adhesive

Industrial hotmelt adhesives are generally used for wrapping wood or MDF profiles. NWA systems can be operated with all common hotmelt adhesives, but reactive polyurethane hotmelt adhesives have prevailed over EVA or PO adhesives in recent years. Thanks to their high resistance to heat, moisture and solvents, they are particularly suitable for products that are installed in kitchens or bathrooms, for example.

PUR hotmelt adhesives also guarantee safe transport in lorry and shipping containers, where critical temperatures are easily reached for laminated wooden profiles and panels. PUR hotmelt adhesives are also ideal for furniture that is exported to Asia, where challenging climatic conditions can prevail. NWA lamination machines are specialised in the use of PUR hotmelt adhesives to guarantee reliable profile wrapping of wood and MDF profiles.

The variety of decors and possible problems

Laminating companies in the furniture industry are facing the challenge of constantly processing new materials and, in particular, decors according to the prevailing trends. This is often accompanied by a necessary change in working parameters and new quality requirements. High-gloss films and supermatt films are particularly susceptible to defects in the surface finish. Inclusions under the decorative film or orange peel effects can easily occur, leading to material rejects and complaints. Other decors such as CPL, real wood laminates or thick plastic films made of PP or PET require special set-ups and processing to counteract delamination after bonding. But how do you overcome this multitude of possible sources of defects?

WPR quality standards

The basic equipment of the NWA WOOD series foil laminating systems already offers essential advantages for processing companies. The robust machine frame prevents vibrations in the lamination process, which can lead to irregularities in adhesive application and foil application. The specially developed systems for the application of PUR hotmelt adhesives work reliably, protect the adhesive and are easy to clean. This means that high-quality results can be achieved with minimal maintenance, meeting the highest customer demands.

Customised system design

In addition, all profile wrapping machines are customised to meet specific customer requirements. A wide range of technical options offers the optimum configuration of the machine, whether in terms of reducing set-up times, increasing production capacity or adapting to special product categories. Thanks to our extensive knowledge of the laminating process, we develop and design the most suitable machine together with our customers, always considering the entire process and the recommended working parameters for the various materials. From material infeed, material cleaning and preheating to gluing and profile cutting, we offer various solutions, including automatic process control and storage of working parameters.

Personal and expert advice

Are you looking for a high-speed profile wrapping machine for laminating MDF profiles? Do you need a flexible machine to handle small batches with many profile changes? Or do you have a completely new idea and cannot find a suitable solution on the market? Then contact our experts without obligation. Thanks to the comprehensive expertise of our sister company TAKA in the manufacturing of PUR adhesives, WPR can offer you sound advice that goes far beyond the mere choice of machine. Simply contact us using the contact form below.